Industrial Applications

We supply pressed and drawn bars, sections and pipes as well as ready-to-install components for a wide range of applications in industry. We manufacture them from a wide range of copper alloys that are specially adapted to the requirements of customers all over the world.

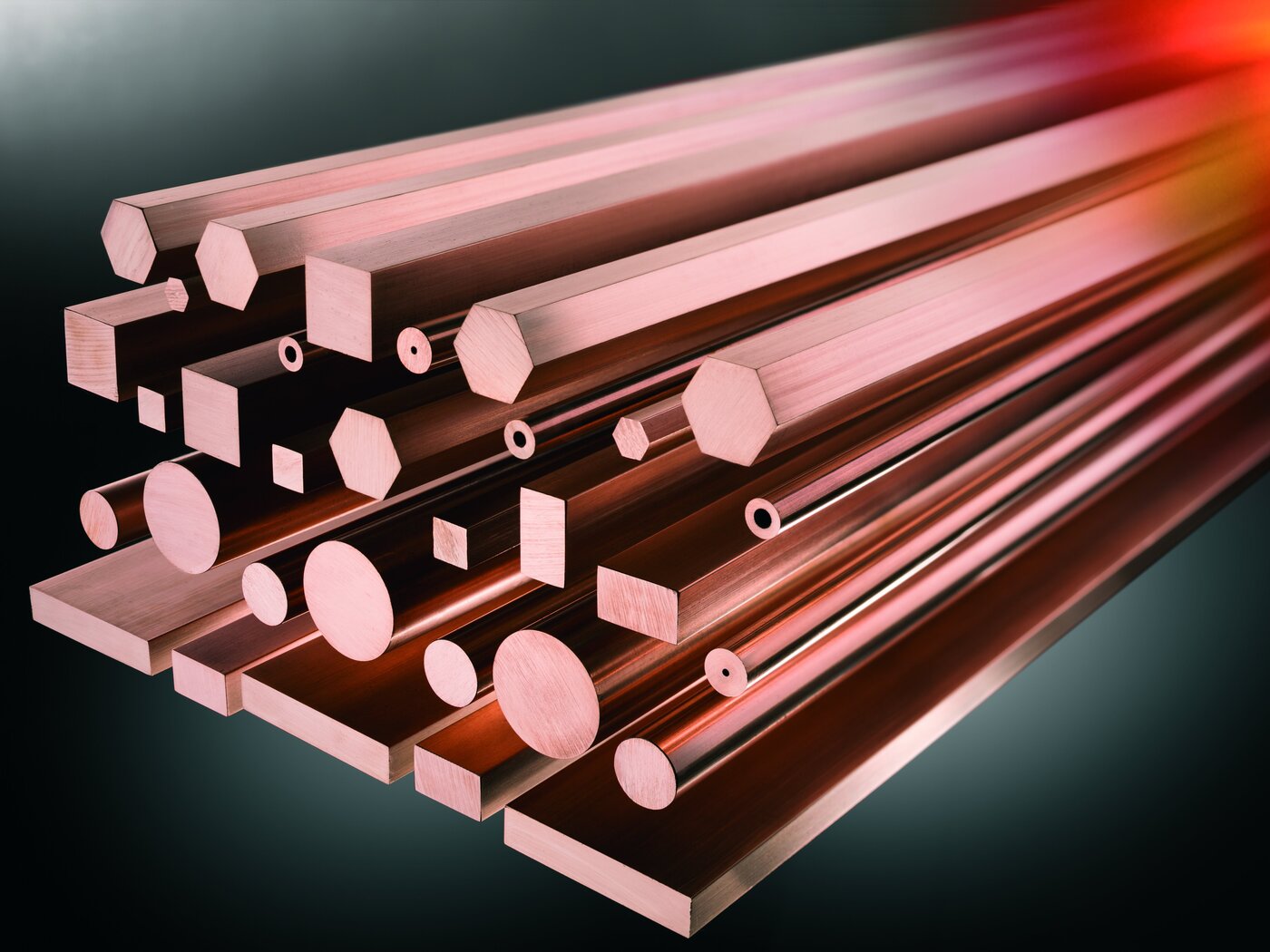

Semi-finished Products

cunova is one of the world's leading producers of copper bars and sections. We use modern machinery to manufacture a wide range of solid or hollow sections adapted to specific applications.

Overview semi-finished Products

OSNA-Cu 58® is a phosphorus-deoxidised copper material with added tellurium or sulphur. Semi-finished products made of this material have excellent machining properties. In the process, the essential properties of copper, especially conductivity, are largely preserved.

For decades, we have manufactured semi-finished products for electrical resistance welding and supplied input material for highly stressed parts in blowpipes for fusion welding.

ELBRODUR® is characterised by high electrical and thermal conductivity, strength, tempering resistance and hot hardness. Its various characteristics are optimally adapted to the respective welding processes and materials.

When the product requirements include high conductivities for electrical current and heat as well as long service life, then sections and round and polygonal bars made of PROCU® provide an optimal solution.

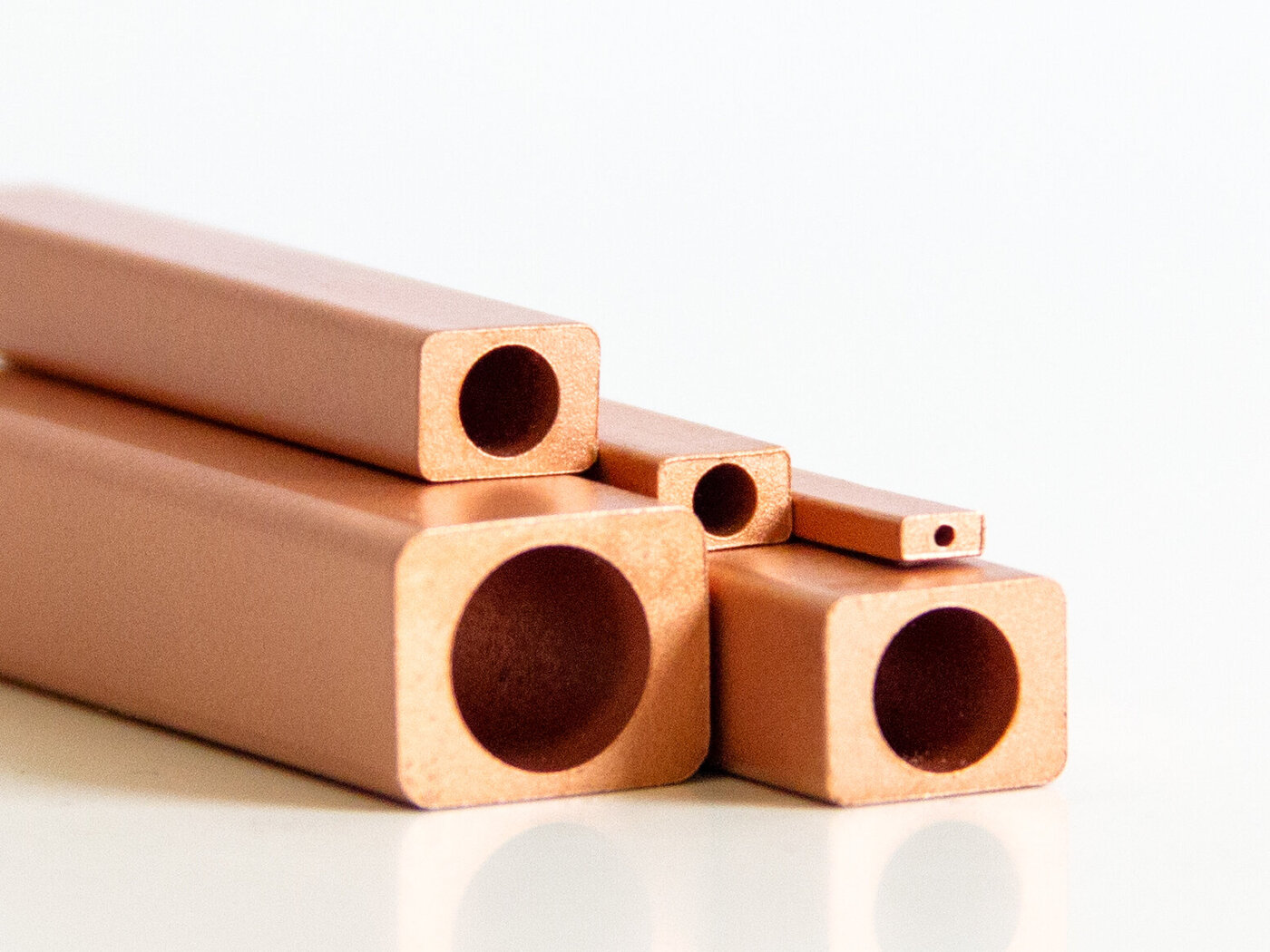

For high-current and high-voltage technology, we manufacture seamless pressed or forged pipes made from highly conductive copper in a wide range of dimensions and alloys.

Our finned tubes in oxygen-free copper cool the furnace walls when remelting metals in electric arc furnaces. The tubes are highly efficient at dissipating heat, have a long service life and are easy to install.

Machined and ready-to-install customised Workpieces

In our high-performance mechanical processing department, we manufacture components with a finished weight of a few kilograms up to several tonnes based on customer specifications. In addition to turning, milling and drilling, we use various copper welding processes. By exchanging ideas with our customers, our specialists optimise these products during the design phase with a focus on technical and economic aspects.

Hollow Profiles

Our hollow copper profiles are specially developed for demanding electrical applications that require strong magnetic fields, such as in MRI scanners, induction coils for ovens and power generators. Thanks to state-of-the-art manufacturing technologies, we offer a wide range of dimensions and shapes, both as rod material (>10 m) and as coil material, depending on the cross-section. Our products are characterised by the highest quality and functionality and are available in different material versions, such as Cu-OF and Cu-ETP, to meet the specific requirements of your applications.

Fact Sheet

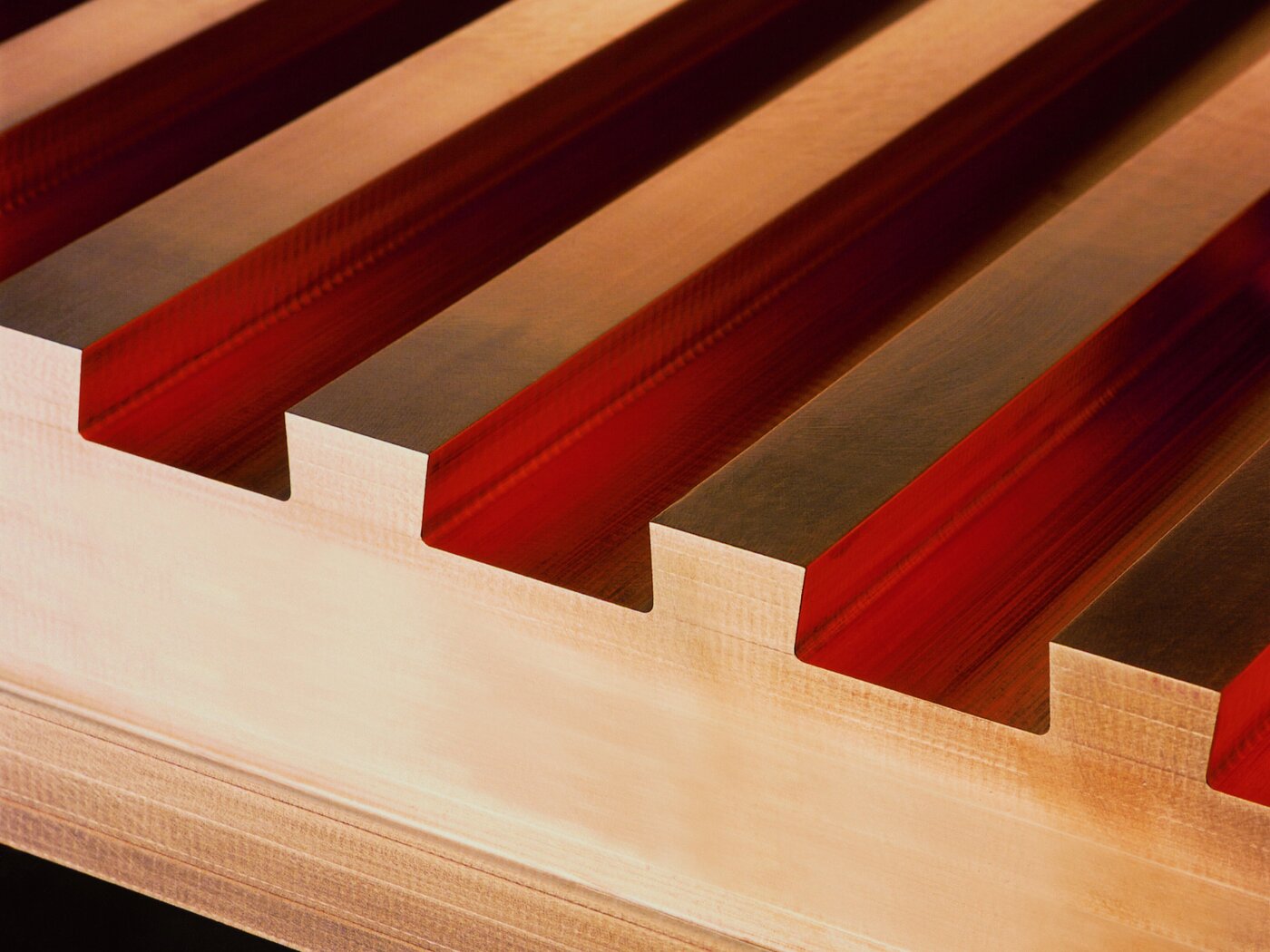

Efficient cooling with Copper Staves

In modern blast furnaces for pig iron production, our copper staves are a tried and tested method for efficient cooling. We pioneered their development and hold the basic patent.

The profiled staves equipped with deep-drilled cooling channels ensure the controlled evacuation of process heat. In combination with high-strength ceramic materials, they offer maximum temperature resistance, media resistance and abrasion resistance.

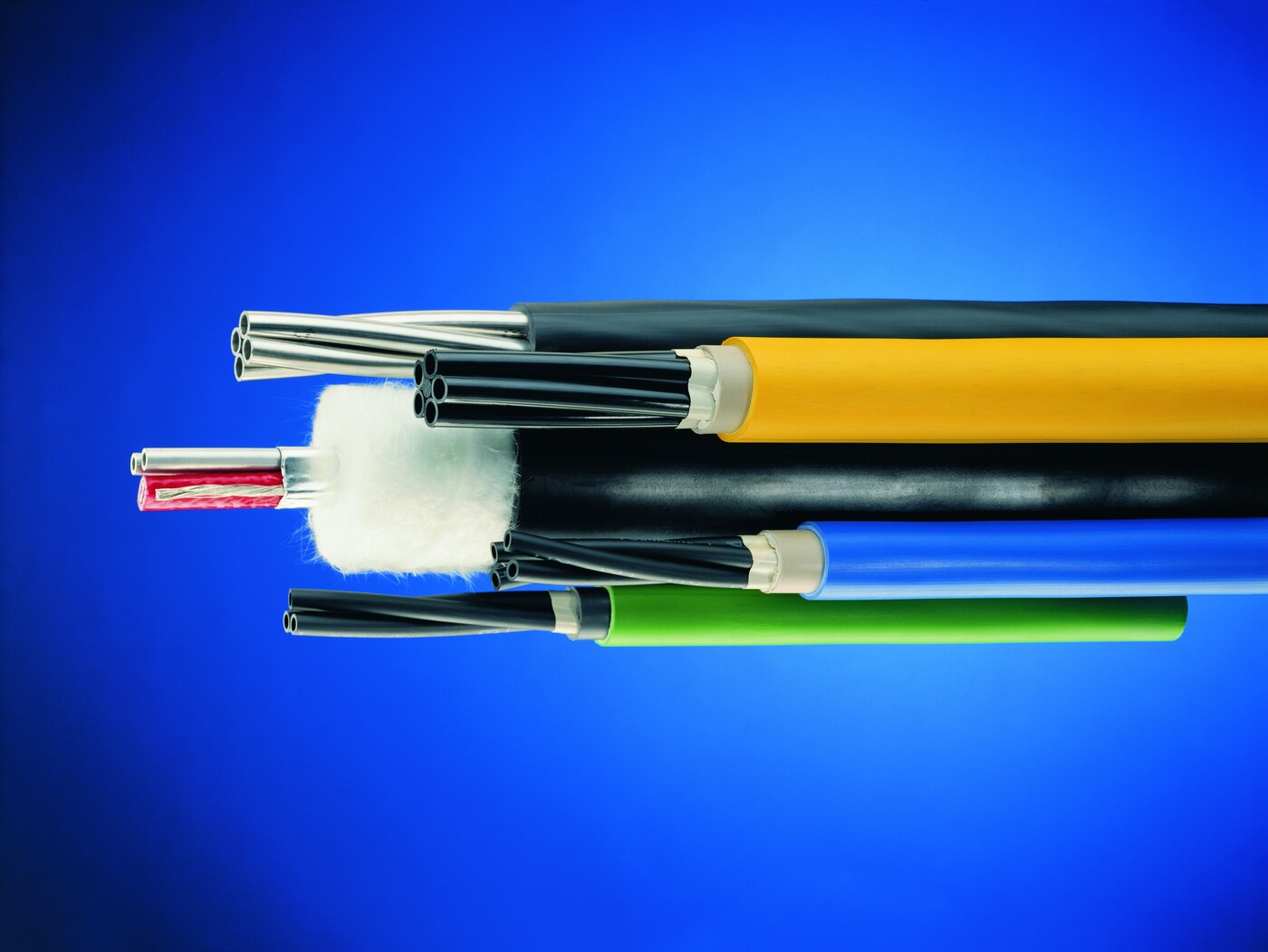

Tube Bundles

In many plants, for example in the chemical industry, in paper mills or breweries, long pipes are needed to transport gases, liquids, energy and data. There has also been a steady increase in demand for natural gas and hydrogen refuelling stations.

With our stranding machine, we produce individually configured tube bundles in delivery lengths of up to 2,000 m according to customer requirements. They contain up to 19 components made from different materials. They reduce installation effort and waste, particularly where long distances are involved. Made out of a single piece, they have no weaknesses.

Powder for additive Manufacturing

Our alloy-based copper powders for additive manufacturing meet the highest requirements in terms of purity, composition and flowability.

Gas atomisation with subsequent air sifting ensures that the powder has almost spherical particles, optimal particle sizes and a good particle size distribution. In addition, they are characterised by high flowability and bulk density. This combination of properties leads to a uniform and dense copper powder layer.

Copper powder enquiry